Steel Frame Construction Methods in Modern Warehouses

By nature, global logistics is a fast-moving industry. Warehouses are vital to facilitate the free flow of goods on an epic scale. In turn, modern warehouses have evolved to achieve huge sizes, with the biggest containing over a million square feet of floor space.

Panattoni, a world leader in warehouse development, is at the forefront of delivering this vital infrastructure. Since 2005, Panattoni has developed over 200 million square feet of industrial logistics space across the UK and Europe – big enough to contain 2,633 football pitches.

Building warehouses on a huge scale involves solving several unique structural challenges, detailed below.

The evolution of portal frames

Amongst steel frame construction methods, portal frames are undoubtedly the key technology behind today’s industrial logistics warehouses.

Originally developed during the Second World War, the portal steel frame construction method gained widespread popularity in the 1960s. Embraced for their structural efficiency, portal frames allow for the creation of large, clear-span enclosures using minimal materials, thus reducing costs.

Today, an updated and developed portal structure is the cornerstone of steel frame construction methods, particularly in the UK, which is commonly regarded as a world-leader in the technology. Tata Steel estimates that 50% of constructional steel in the UK is used in portal frame construction.

How do steel portal frames work?

From all the different steel frame construction methods available, portal frames stand out for their ability to span vast distances quickly and cost-effectively.

In their simplest form, a portal frame consists of a beam, or rafter, supported by columns at each end. What sets a portal apart from other steel frame construction methods is the rigid connection between the beam and columns, allowing the bending moment in the beam to be transferred to the columns. This innovation enables the beam to span vast distances with a reduced sectional size, making the portal steel frame construction method ideal for wide-span enclosures like warehouses.

Fabricated from steel, portal frames are enhanced by haunches, brackets, or deepened sections at the joints to maintain rigidity.

What is a haunch?

A haunch is a reinforced section of a portal frame structure, typically located at the connection between the beam (rafter) and the column. The haunch is designed to increase the strength and stiffness of this critical joint, where significant forces are transferred between the beam and the column.

The useable internal height of a warehouse is dictated by the ‘haunch height’, which is why you will often see this important figure quoted in marketing materials.

How far apart are warehouse columns spaced?

In the UK, a standard warehouse frame features an internal column spacing of 32 by 16 metres, providing a flexible space suitable for a wide range of goods racking, including Wide Aisle and Very Narrow Aisle (VNA) pallet configurations. To put that into context, you could park three and a half London buses nose-to-tail within a single 32 metre span.

What are the different types of steel portal frames?

Among steel frame construction methods, the type of portal frame employed depends on factors like load requirements, span dimensions, and architectural preferences.

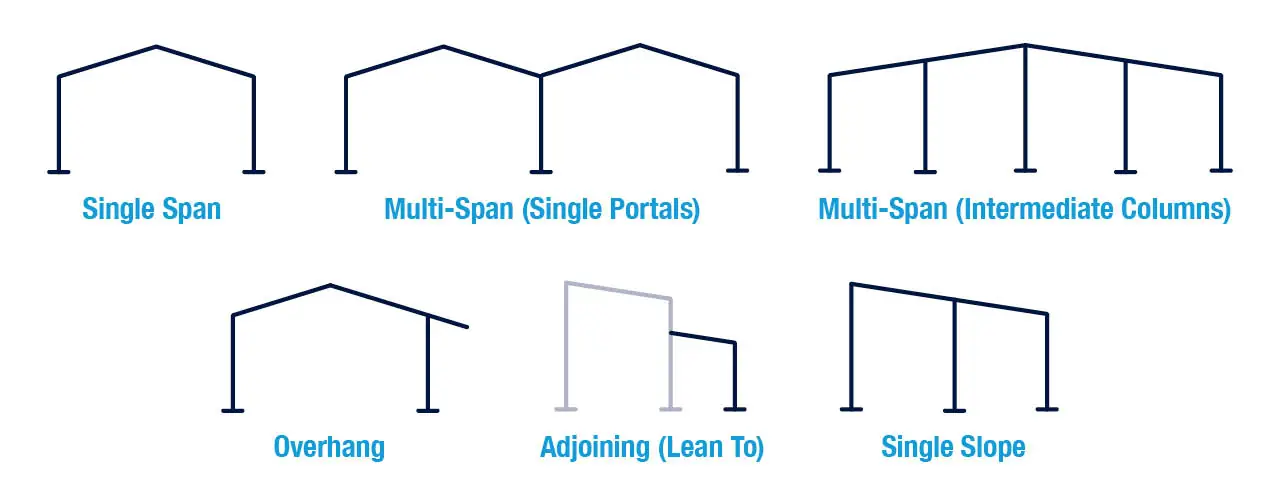

Various portal frame types include:

Single-Span

The single-span portal frame is the most straightforward and commonly used type in steel frame construction methods. This frame consists of two columns and a horizontal or slightly sloped beam that spans between them, creating a clear span. The design’s simplicity offers flexibility in interior space planning. On a small scale, single span portal frames are suitable for structures like residential garages and workshops. Used together with shared columns, they can cover huge areas, such as logistics warehouses, the multiple pent roofs reducing overall height.

Multi-Span

For larger spans that exceed the capacity of a single-span frame, a multi-span portal frame can be employed. This design connects multiple single-span frames with intermediate columns and beams, allowing for a larger clear span. It is particularly effective for light commercial buildings, such as retail spaces, showrooms, and small industrial structures, where more expansive open areas are required. The downside over multiple single spans is a pent roof with a higher apex, creating additional height.

Tapered

A tapered portal frame utilises beams and columns with variable sections that taper from the base to the ridge. This strategic design increases material efficiency by enlarging section areas at points of maximum bending moment. Steel frame construction methods often leverage tapered frames for both their structural efficiency and aesthetic appeal, making them ideal for architectural applications like entry canopies, covered walkways, and grand entrances.

Curved

In steel frame construction methods that prioritise aesthetic considerations, the curved portal frame offers a visually striking alternative. Featuring a curved horizontal beam, this type of frame is used in applications such as atriums, roof canopies, and other architectural features where a distinctive curved design enhances the structure’s appeal.

Lean-To

The lean-to portal frame is a practical solution for adding space to an existing structure. It consists of a single sloping roof supported by a primary portal frame. This type is frequently utilised in residential projects to extend living areas, create carports, or provide additional storage spaces, seamlessly integrating with the existing building.

Canopy

Designed to create covered outdoor areas, the canopy portal frame typically features a single-span structure with an extended horizontal beam to offer shelter. This frame is common in residential projects for covered porches, carports, and outdoor living spaces, where protection from the elements is necessary.

Truss

In scenarios requiring exceptionally large spans, truss portal frames are employed. Incorporating trusses in the rafters and ridge, this design allows for the largest spans achievable in portal frame construction, making it ideal for large uninterrupted spaces such as aircraft hangers.

How are the walls and roof constructed?

While portals form the core steel frame construction method, the way the walls and roof are built are just as important.

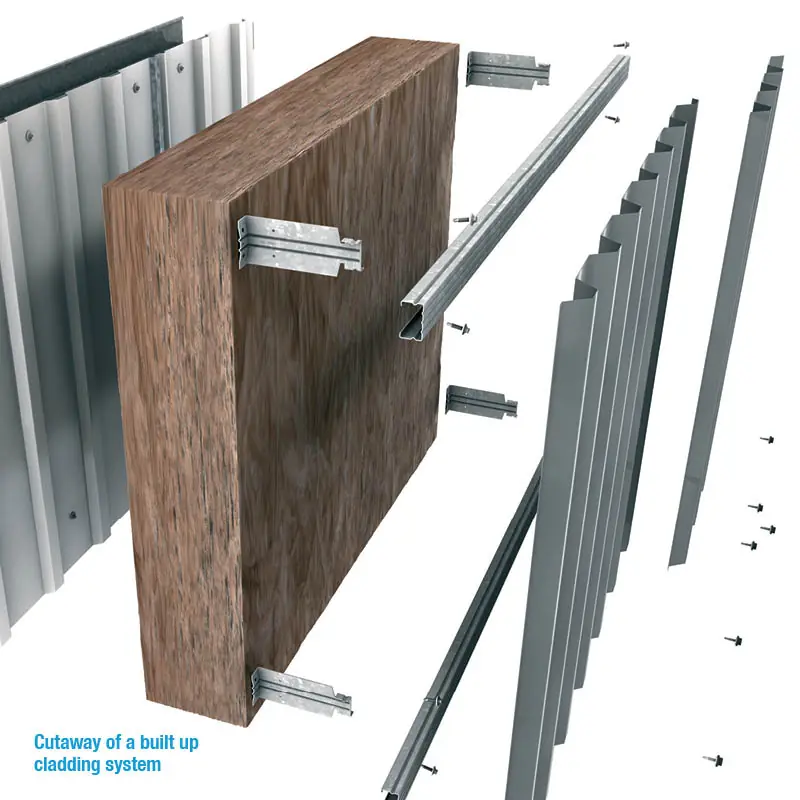

The exteriors of modern warehouses use a built-up cladding system. A thick layer of insulation is sandwiched between two layers of galvanised painted steel affixed to a frame. Both the walls and roofs are built in this way, with roofs also featuring sky lights (known as ‘rooflights’) to maximise daylight within the internal space.

Built to keep goods in – and the weather out

Modern portal steel frame construction methods are engineered to withstand a variety of load conditions, including those imposed by the weather – think about the wind load on a 20-metre-tall building, or the snow load on a 32-metre span.

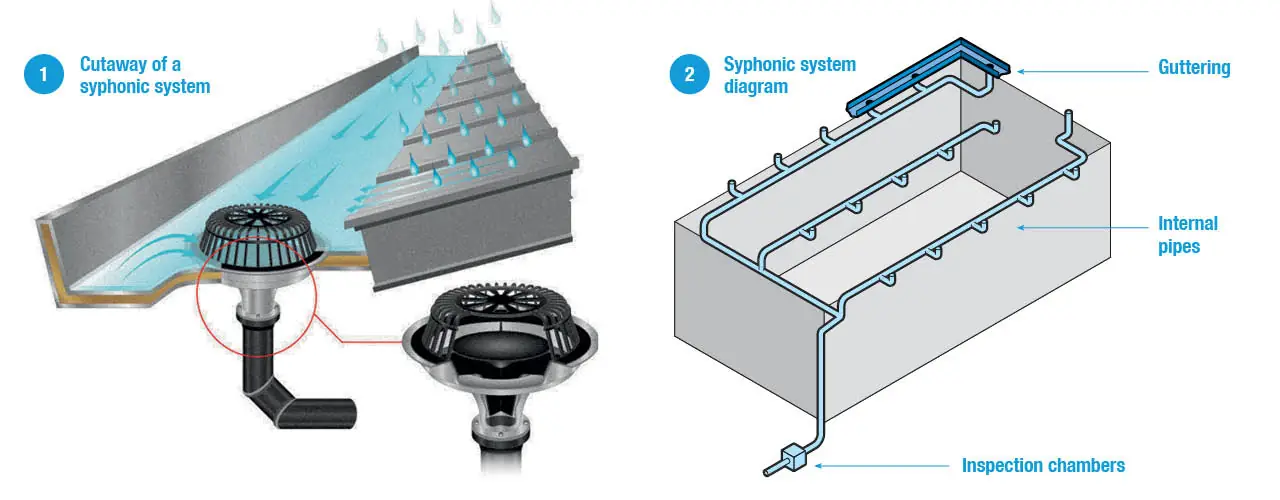

Warehouses also catch a lot of rain on their roofs, particularly during storms. Contemporary buildings feature a high-capacity symphonic drainage system to quickly remove water, with many newer warehouses also capturing some of this so called ‘grey water’ for later use within the warehouse.

Sustainable steel frame construction methods

A responsible approach to sustainability is key to achieving the long-term goals of all stakeholders. Steel frame construction methods are increasingly designed with this in mind.

Driving down carbon emissions

Panattoni’s Target Net Carbon Zero initiative optimises material selection and processes, with the purpose of driving down both embodied carbon and carbon emissions during construction. Panattoni’s VPark industrial units in Basingstoke are a good example of this best practice.

Panattoni is also committed to updating their steel frame construction methods to use low carbon steel resources as they come on stream.

Sustainable structure

Modern warehouse buildings are designed with sufficient loading and infrastructure to support solar panel installations covering up to 100% of the entire roof area.

The most energy efficient structures are designed to maximise airtightness – the ability of the building envelope (the walls, roof, windows, doors, and floors) to prevent air from unintentionally escaping or entering the structure. High airtightness is crucial for controlling the internal environment of the warehouse, including temperature and humidity, thus maximising energy efficiency.

Airtightness is tested by increasing the air pressure in the building with a giant fan – like blowing up a giant balloon – then measuring the rate at which the pressure decreases.

Panattoni: world-leading steel frame construction methods

As the largest developer of logistics space in the UK and Europe, Panattoni’s portal steel frame construction methods have become the industry yardstick for quality and performance. By implementing the latest structural technologies, the company delivers buildings that are sustainable, adaptable, and ready for tomorrow.

Looking to the future, Panattoni remains committed to raising the bar for steel frame construction methods, defining and redefining warehousing for years to come.